MG AEC

Mainstreaming sustainability with generative design capabilities

CUSTOMER STORY

Share this story

Summary

Optimized sustainability and certainty of performance improve the value of the built environment. MG AEC relies on Autodesk’s Architecture, Engineering, and Construction Collection to improve building design by enabling informed decision processes integrated into the workflow. Using a proof-of-concept case study, the team at MG AEC shows how design approaches can quickly and efficiently be evaluated using the automated data processing tools within The AEC Collection. This creates more freedom for the design team to explore options that best achieve sustainability and project goals without sacrificing precious time and money.

MG AEC's recently developed proof-of-concept case study, known as SolVista, shows that high-performance building design can, and in the face of climate crisis, must, become mainstream.

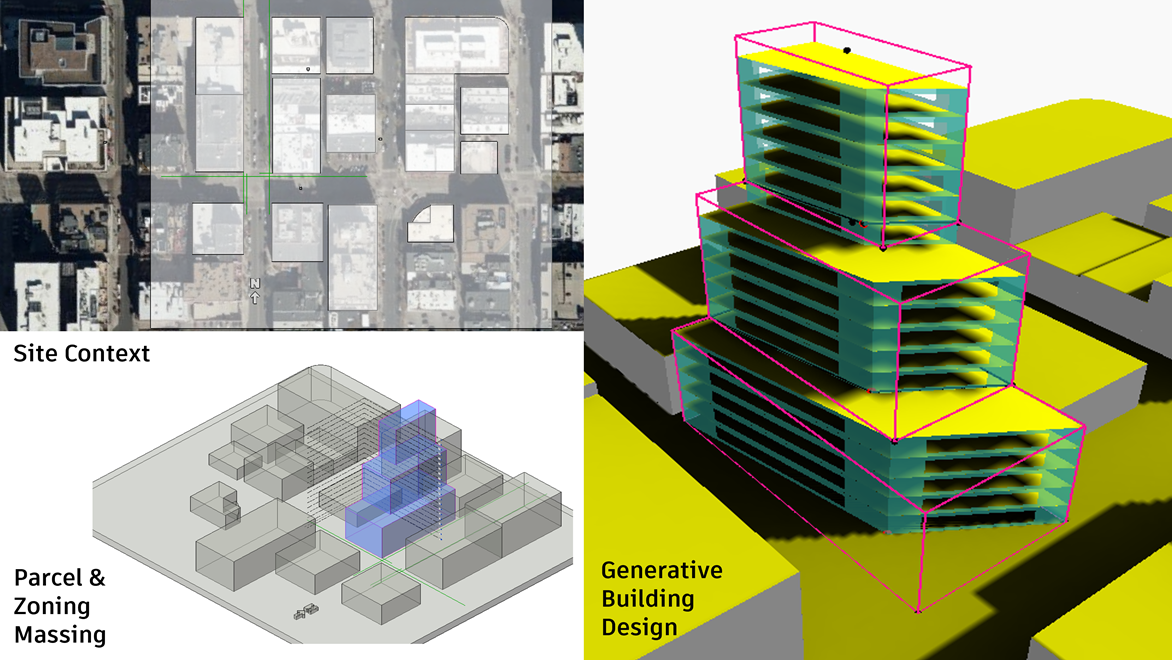

The SolVista case study explores design options using generative design capabilities for a multi-story building located in Denver, CO. Image courtesy of MG AEC

Driving towards sustainable outcomes

A consulting firm that helps bridge the gap between design and manufacturing, MG AEC Technology Partners, a subsidiary of D3 Technologies, is a leader in assessing and enhancing workflows and processes, partnering with design and construction teams to support technical staff and end-users.

The SolVista case study integrates powerful tools available in Autodesk’s AEC Collection, including Generative Design in Revit and additional workhorse capabilities in Dynamo for Revit, to reveal design possibilities, inform the team, and result in better decisions that achieve desired outcomes.

The case study involves a multi-story building located just west of Denver’s central business district. Project design goals include evaluating options that maximize indoor daylight, meet desired window-to-wall ratio requirements, and incorporate renewable energy via rooftop solar panels.

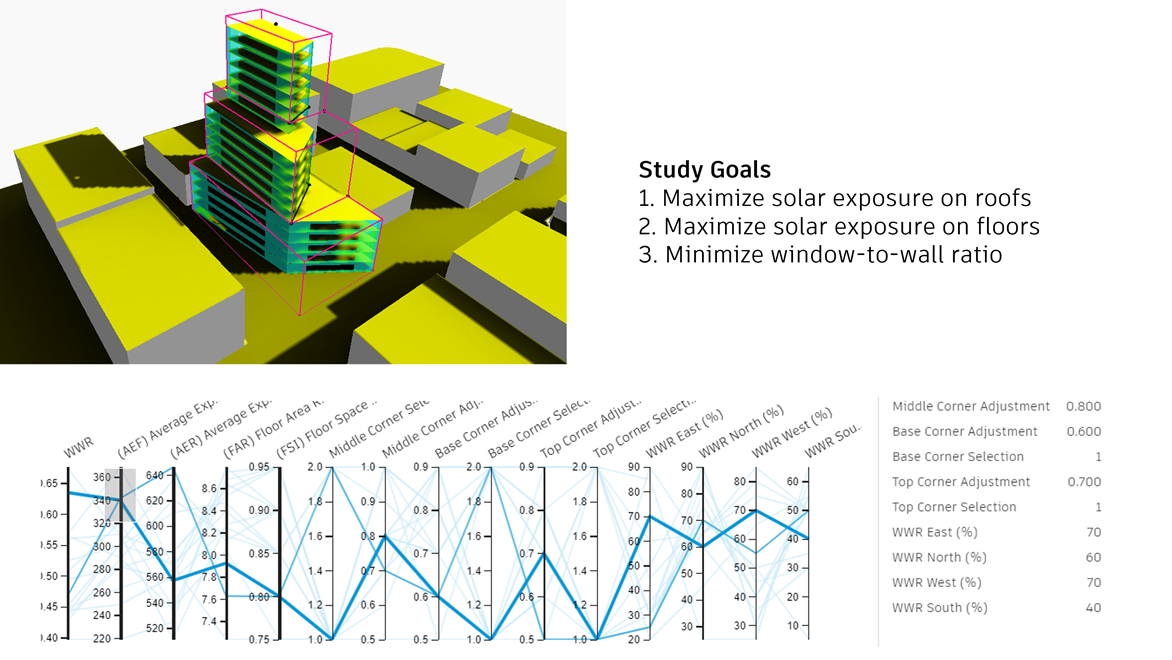

Project design goals include maximizing indoor daylight, meeting desired window-to-wall ratio requirements, and incorporating renewable energy via rooftop solar panels. Photo courtesy of MG AEC.

Making informed design decisions

“Using data, we can look at the building and develop a design concept that meets the needs and requirements of our clients,” says Jarod Schultz, at MG AEC. The workflow starts with inputting fixed constraints such as zoning and parcel restrictions, floor heights, and other limitations. Designers can include, prioritize and sort building orientation and any other “must-haves" or “nice-to-haves." These inputs provide flexibility, opening up potential design approaches that may not otherwise have been considered because of time constraints.

“Generative design is a great way to show us options but, ultimately, it is us as humans that have to make those final decisions about how this design is going to best fit with the needs that we have,” Schultz says.

Exploring potential sustainable design solutions

The tools embedded in the AEC Collection help MG AEC quickly produce visuals that are highly effective for showing the impacts of different design decisions.

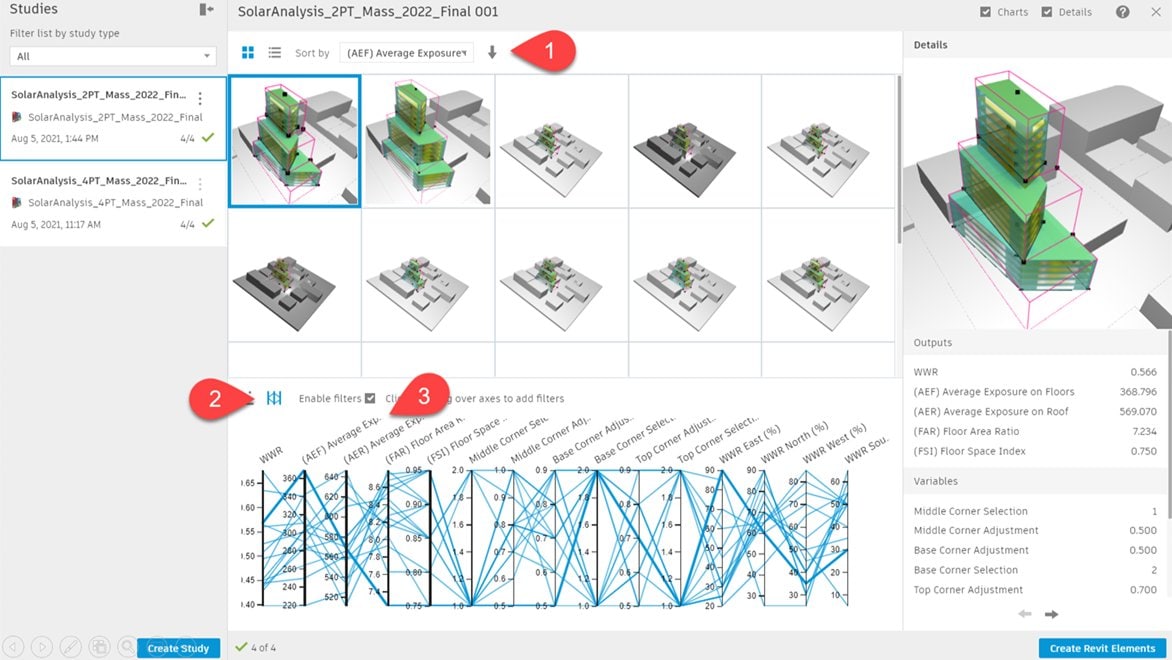

“What’s really nice about Generative Design in Revit is, we’re not only able to develop great visuals for presentation, but also hard numbers from the structured data,” Schultz says. “We’re able to filter the data and narrow the options down to maybe two or three different design directions that come close to the outcomes we want,” he adds.

Once the design concept is decided, the team can then use Generative Design in Revit to make the building perform as best as possible. The flexibility of inputs and the subsequent automated processes allow for the evaluation of a variety of customizations.

In the case of the Denver site, there are several inputs including floor-to-floor height and different sizing for the bottom, middle, and top of the building form, restrictions based on the mass representing the parcel, and zoning conditions. The exploration of options between a flat roof versus a two or three-tiered roofline provided data to evaluate the potential for solar panels in each scenario.

“Generative design is a great way to show us options but, ultimately, it is us as humans that have to make those final decisions about how this design is going to best fit with the needs that we have.”

—Jarod Schultz, Director of Industrial Construction, MG AEC

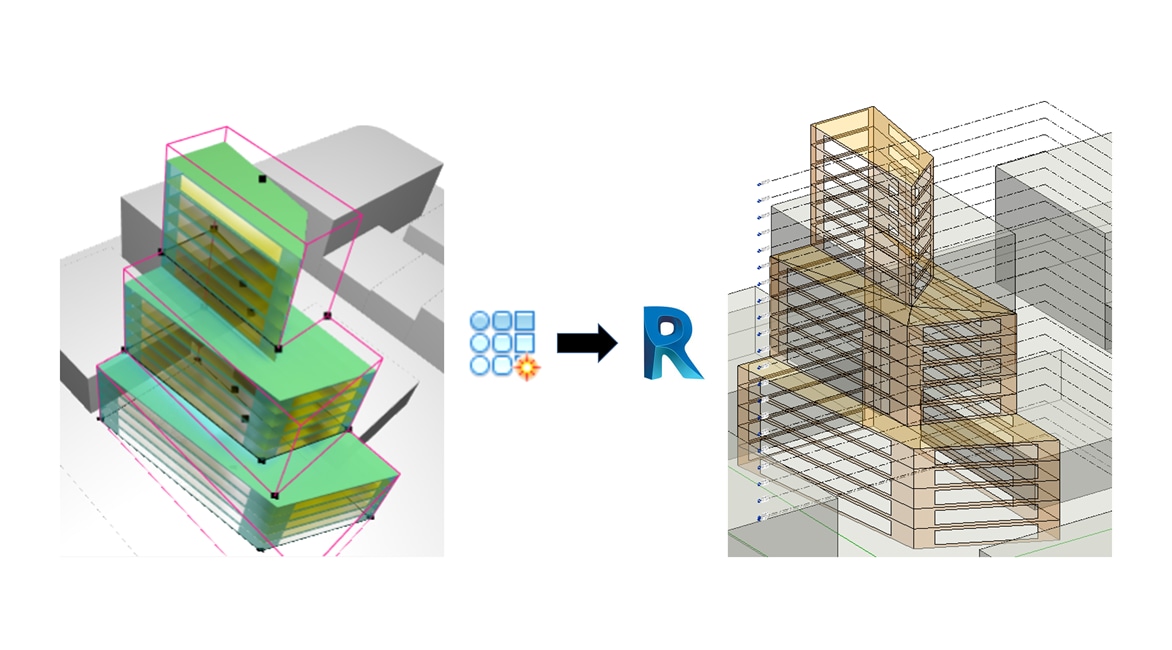

Interoperability between Dynamo and the Revit model help automate analysis studies to meet sustainability goals. Photo courtesy of MG AEC.

Achieving goals with generative design and automation

Another way generative design capabilities bridge the gap between aspirational industry-specific sustainability goals and achievable workflows is the interoperability between Dynamo and the Revit model. “Selected study outcomes can easily be translated as Revit geometry," says Schultz,” , adding, “you can create those elements that you can bring into your Revit model to seamlessly move forward with the design.”

An added bonus is that once the preferred settings are determined, they can be exported back into Dynamo for use in the creation of new Dynamo graphs based on those settings.

Designing with desired outcomes in mind

By designing with desired outcomes in mind at the beginning of the project, the team made adjustments to the overall design direction and provided valuable insights on the constructability. The results provided greater certainty that the outcomes would meet the project’s original sustainability goals: Maximizing the solar exposures on floors and roofs, minimized window-to-wall ratios on each facade, and ensuring the maximum floor area ratio.

Generative Design in Revit and Dynamo workflows within the AEC Collection is a data-driven process that results in better informed human decisions. “We as humans, we have to decide which of these outcomes we want to go with,” says Schultz. “The tools within The AEC Collection provide us with the insight to decide what the possibilities along with the confidence to know, yes we can do this.”