STRATFORD FESTIVAL

AutoCAD helps set the stage for Canadian theatre

AUTOCAD CUSTOMER SUCCESS STORY SHARE THIS STORY

Share this story

Set design comes to life with AutoCAD

Andrew Mestern, technical director for Stratford Festival in Ontario, Canada, doesn’t shy away from creative and technical challenges. He embraces both. By using AutoCAD and experimenting with other technologies such as 3D printing, Mestern delivers incredible sets that awe audiences and bring the stage to life.

Tackling creative challenges with AutoCAD

For more than 20 years, Andrew Mestern, has focused solely on set design both in Canada and the United States. Exclusively working as the technical director at Stratford Festival in Ontario, Canada for the past 10 years, he’s always presented with creative and technical challenges to achieve high-caliber set designs for the theater. With those challenges, he also finds new opportunities to experiment—whether it's with a CNC machine or 3D printer. And he always relies on AutoCAD to deliver sets that amaze.

"I mainly draw everything in AutoCAD," Mestern says. "It creates an assembly drawing to show how to put all the parts together when it comes to installation. It's like model building, but scenery instead."

But he doesn't stop there when it comes to using AutoCAD for set design.

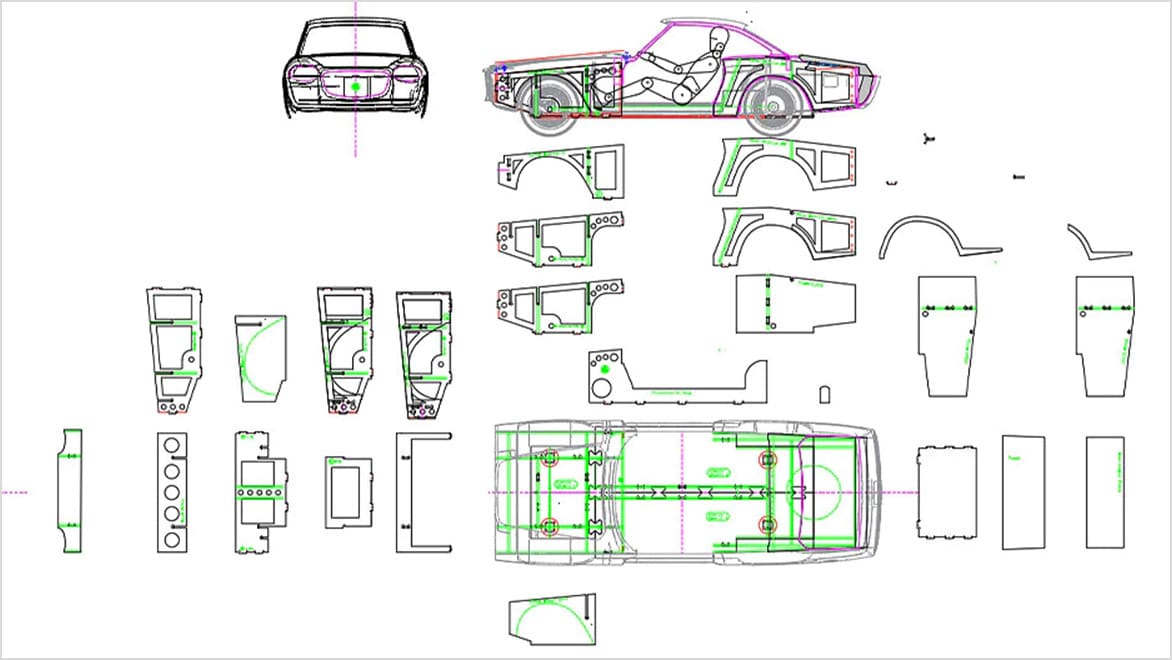

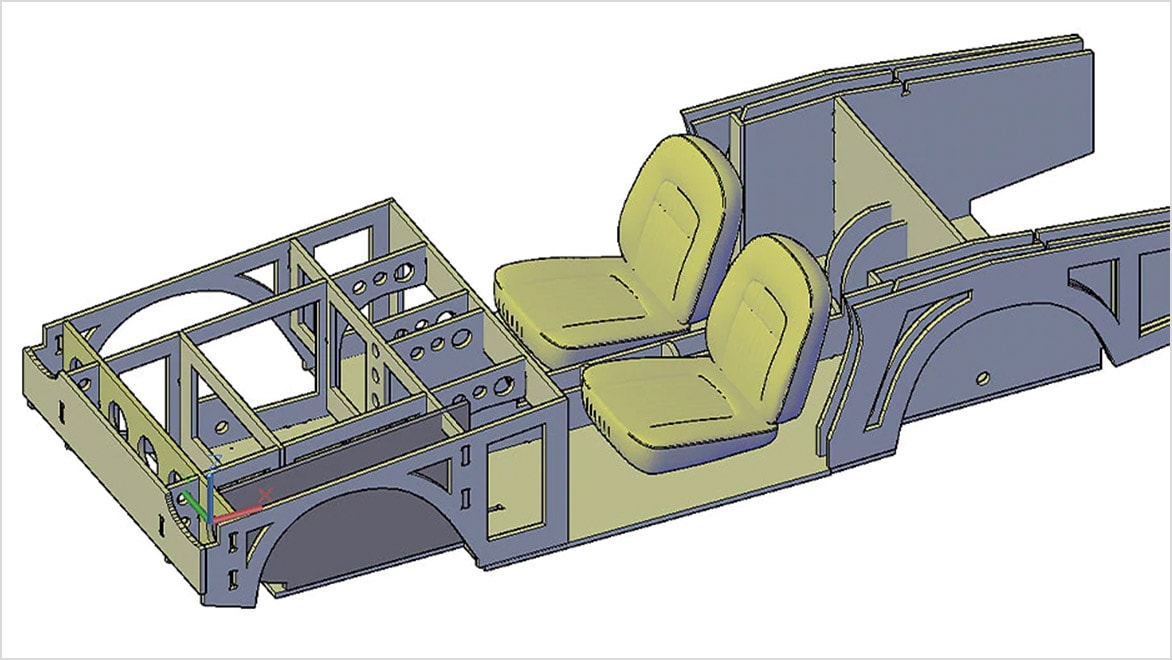

AutoCAD drawings (top) and rendering (bottom) of 1969 Lancia C3 model for set design. Courtesy of Andrew Mestern.

3D all the way

Sometimes 2D just isn't enough. According to Mestern, 3D models and renderings make communication much easier. He uses AutoCAD's 3D modeling features to turn what are typically just 2D plans into 3D representations of the set.

"Sometimes I don't fully understand what a set designer wants or know the limitations of what the carpenters or painters can do," Mestern says. "If I fully render a piece of scenery, add materials, and lighting, we can get a better visual of what's happening. This can be huge for the designer and our team to truly understand what we can and can't do."

When it comes to set design, you also want to ensure that the audience is taken into account. 3D renderings allow all involved to ensure the audience have the optimum view and experience.

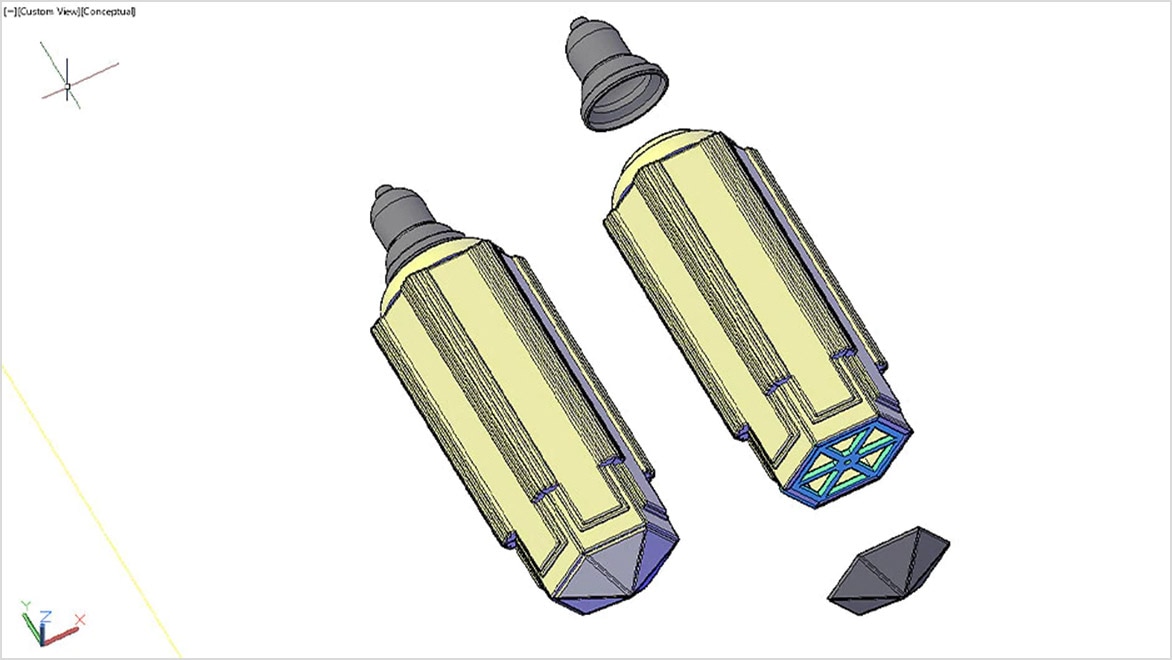

3D rendering of chandelier in AutoCAD. Courtesy of Andrew Mestern.

"A huge part of rendering a set is sitelines," Mestern says. "Currently, I am using AutoCAD to render a railing that goes across the front of the stage. The designer and I are trying to figure out what the most expensive front row seats are going to see before we build the railing. I do this a fair bit when 2D PDFs won't do, including things like a walk-through of a proposed new stage or a display piece to win a contract."

Bringing a 3D model to life

Mestern also uses 3D in another way: creating physical objects, whether it's a prop or a mechanical component for the set.

"Once I've modeled something in 3D in AutoCAD, I just have to export it as a STL file and send it to the 3D printer," he says. "Sometimes I'll do half-scale models to show someone an example of the design or create something that is bespoke."

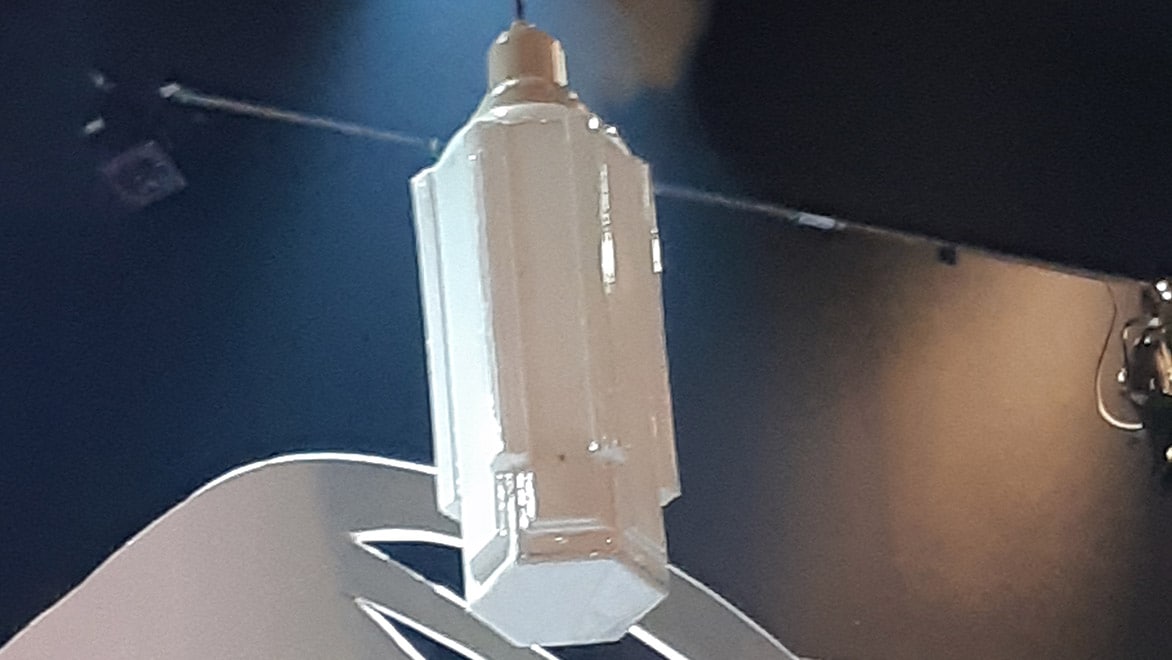

Recently, Mestern finished a tall, tear-drop shaped, Art Deco-style chandelier that is made to look like white glass. For this he combined the use of his CNC machine and 3D printing.

"I drew it in AutoCAD based on a photo the designer chose from a book," he says. "I then sent the STL file to my CNC machine to cut the pieces in MDF. At the same time, we 3D printed the large cap at the top of chandelier. It was really amazing how it turned out, and it looked just like we had imagined it."

Finished Art Deco chandelier. Courtesy of Andrew Mestern.

AutoCAD and beyond

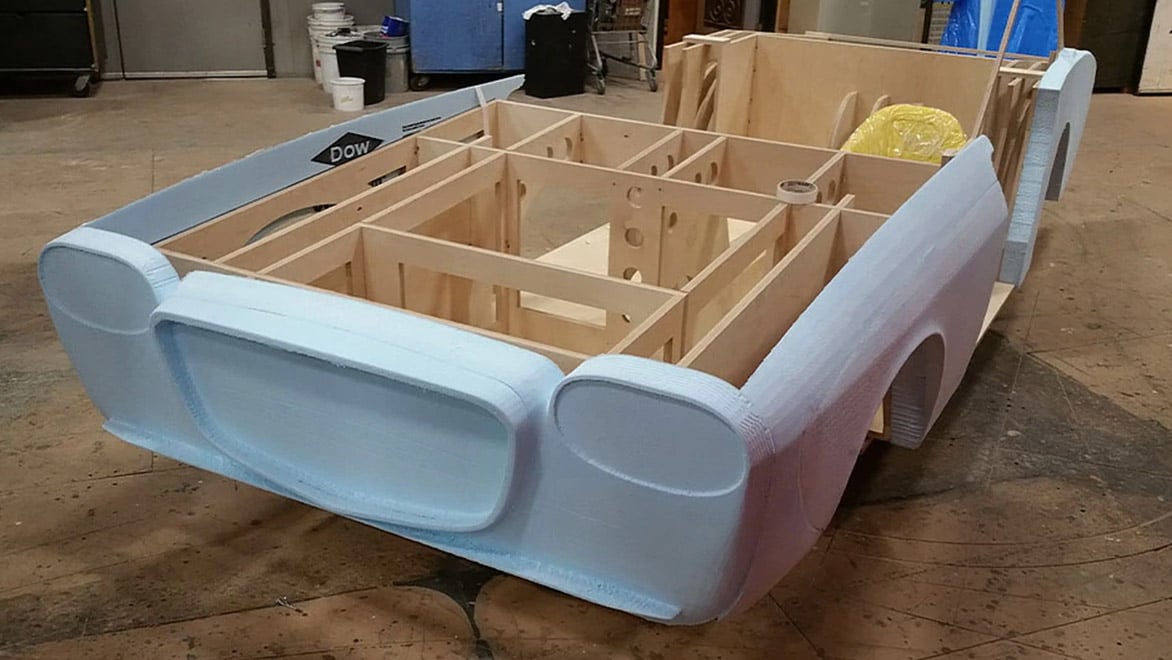

His work on the recent Shakespeare tragedy Coriolanus also showcased how he brings together many technologies for set design. In this modern adaption, a car was an important part of the play—and it had to be an exact replica of a 1969 Lancia C3. He attempted to actually buy a real car and located one in Europe. Problem there? It cost $200,000. Instead he purchased a model of the car as a 3D asset.

"With AutoCAD, I was able to strip down the model; make some body changes; build a chasis; CNC most of the car from Styrofoam or make molds for fiberglassing; and 3D print things like the tail lights," Mestern says. "Being able to work in AutoCAD and do all of the project with just one platform was perfect."

Whether it's a car, a chandelier, and many things in between, it all comes back to AutoCAD.

"I use AutoCAD because I can transition easily from simple ground plans to complex 3D models within the same drawing," Mestern says. "From a single drawing I can create 2D plans to be cut on a CNC machine and, at the same time, export a 3D file for a printer or a render for a director or designer. I can show the designer almost exactly what we are building because we are interpreting their drawing and putting our own constraints on the scenery. The more clearly I can communicate the information with the designer and with the builders the better the final piece will be."

Car in production (top) and final version (bottom) from Coriolanus. Courtesy of Andrew Mestern.